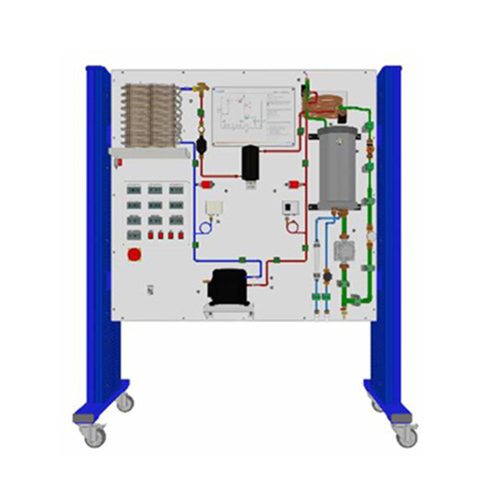

MECHANICAL HEAT PUMP STUDY UNIT Educational Equipment Thermal LaboratoryEquipment

ZF1201A MECHANICAL HEAT PUMP STUDY UNIT Educational Equipment Thermal Laboratory Equipment for college, vocational training center, university.

- Description

- Inquiry

ZF1201A MECHANICAL HEAT PUMP STUDY UNIT Educational Equipment Thermal Laboratory Equipment

To Study the Mechanical heat pump and find its COP

0.3-0.5 TR

COMPRESSOR: – Hermetically sealed compressor with its standardized electrical accessories.

CONDENSER: – Water immersed/cooled type, shell and heat coil heat exchanger.

EVAPORATOR: – Water immersed/cooled type, shell and heat coil heat exchanger.

WATER PUMP: – Two Nos. One for Condenser, 2nd for Evaporator, which shall be connected separately for both Rotameter.

Main switch , Voltmeter-Digital Type, Amp Meter-Digital Type, Switches, Indication Lights, Energy-Meter for Compressor Input, Suction gauge for flow Pressure Measurements, Discharge gauge for High Pressure Measurement, Capillary Tube, Expansion Device, Drier, Gas Charging Valve.

Provided with selector switch for various temperature applications

Glass Tube Rotameter to measure the flow of liquid refrigerant: – One in No

Glass Tube Rotameter to measure the water flow rate: – Two Nos. (One for Condenser water and second for Evaporator water circulations

VOLTAGE: – Single Phase 220 Volts 50 Hz

REFRIGERANT: – Freon – 134 A

To study all components used in mechanical heat pump system

To study the mechanical heat pump cycle

Related Products

Trainer for Various Heat Exchangers Thermal Lab Equipment Educational Equipment

ZF1115A Trainer for Various Heat Exchangers Thermal Lab Equipment Educational Equipment

Specification

[1] examination and comparison of various heat exchanger types

[2] five different types of heat exchangers included in the scope of delivery

[3] finned heat exchanger with fan

[4] operating mode (parallel flow or counter flow) selectable via valves

[5] flow rates adjustable via valves

[6] electromagnetic flow meter

[7] digital displays for temperature, pressure differences and flow rate

[8] hot & cold water benches available for

independent operation

[9] water/steam heat exchanger unit and electrical steam

Generator available for further experiments

[10] software for data acquisition via USB under Windows Vista or

Windows 7

Technical Data

Plate heat exchanger, 10 plates

– heat transfer surface area: approx. 0,26m²

– capacity: 15kW

Tubular heat exchanger

– heat transfer surface area: 0,1m²

– heat transfer surface area (coil): 0,17m²

Shell and tube heat exchanger

– capacity: 13kW

Finned cross-flow heat exchanger

– heat transfer surface area: approx. 2,8m²

– max. flow rate fan: 780m³/h

– max. pressure difference fan: 430Pa

Jacketed vessel with stirrer

– heat transfer surface area (vessel): 0,16m²

– heat transfer surface area (coil): 0,17m²

Measuring ranges

– differential pressure air: 0…10mbar

– differential pressure water: 0…1000mbar

– flow rate: 0…3m³/h

– temperature: 0…100°C

Dimensions and Weight

LxWxH: 2010x800x1760mm

Weight: approx. 300kgBrand: Shouldshine

Model:ZF1115AInstallation technology losses in different pipes Vocational Training Equipment Didactic Equipment

SR3003 Installation technology losses in different pipes Vocational Training Equipment Didactic Equipment

Brand: ShouldShine

Model:SR3003

investigation of the pressure losses of flow through pipes

– measurement of the pressure differential on different pipe sections

– influence of various pipe diameters

– influence of different materials and surface roughness

– effect of the flow velocity

– comparison between experiment and theory

Specification

[1] investigation of friction-induced pressure losses in flow through pipes

[2] pipe elements are commercially standard components in heating and sanitary engineering

[3] clear panel mounted on a sturdy, movable frame

[4] four measuring sections with different pipe crosssections and materials

[5] pipe sections can be selected via ball valves

[6] water connections made using quick-release couplings in the inflow and return

[7] flow can be adjusted via valves

[8] flow measurement using rotameter

[9] differential pressure measurement via differential pressure meter with display

Technical Data

Pipe sections measuring length: 1000mm

– pipe section 1: transparent plastic, diameter: 20×1,5mm

– pipe section 2: steel, diameter: 1/2″

– pipe section 3: copper, diameter: 18x1mm

– pipe section 4: copper, diameter: 15x1mm

Differential pressure meter

Measuring ranges- flow rate: 150…1600L/h- differential pressure: -350mbar…350mbar

Dimensions and Weight LxWxH: 1650x700x1850mm Weight: approx. 92kg

Required for Operation

Water connection: 1500L/h, drainFour way mixing valve training panel Educational Equipment Teaching Equipment

SR3006 Four way mixing valve training panel Educational Equipment Teaching Equipment for college, university.

Fitting Loss Training Panel Educational Equipment Vocational Training Equipment

ZF1119A Fitting Loss Training Panel Educational Equipment Vocational Training Equipment

Specification

Training panel for investigating the pressure losses in pipe fittings such as elbows and bends

4different measuring sections, measured length of each section 2300mm, 10 elbows/bends

Pressure measurement with annular chambers with electronic differential pressure gauge

Flow rate measurement with Rota meter

Hose connections made using quick action coupling

Water feed via pressure reducer

Cold water connection

Differential pressure gauge with bleed – measuring range: 0…2000mbar – supply: 9V, battery-operated

Rota meter: measuring range 150…1600ltr/h

Outlet pressure at pressure reducer: 0.5…2bar

Pipe sections: measured length: 2300mm – Pipe section 1: steel, bend

1/2″, 90° bend – Pipe section 3: copper 18x1mm, 90° elbow – Pipe section 4: copper 18x1mm, 90° bend

Pipe and Fittings

7mm bore test section

13.6mm bore test section

13.6mm bore test section with four bends

13.6mm bore test section with four elbows

13.6mm bore test section with ball valve

13.6mm bore test section with angle seated valve

Expeirmental Capabilities

Determination of pressure drop across various pipes and fittings at differnet flow rates

Flow rate/diameter relationship determination for flid flow in pipes

Estimation of loss coefficient (K) for various pipes, pipe fitting and valve settings

Friction Factor determination for fluid flow in smooth pipes

Brand: Shouldshine

Model:ZF1119AInstallation technology losses in pipe bends Technical Teaching Equipment Didactic Equipment

SR3004 Installation technology losses in pipe bends Technical Teaching Equipment Didactic Equipment

Brand: ShouldShine

Model:SR3004

Learning Objectives / Experiments

– flow measurement

– differential pressure measurement

– effect of flow and surface roughness

– effect of the flow velocity

– effect of changes in pipe direction

Specification

[1] investigation of the pressure loss at pipe elements with different changes in pipe direction and materials

[2] pipe elements are commercially standard components in heating and sanitary engineering

[3] clear panel mounted on a sturdy, movable frame

[4] simply selection of the measuring sections via hose connection with quick-release couplings

[5] flow can be adjusted via valves

[6] flow measurement using rotameter

[7] differential pressure measurement via differential pressure meter with display

Technical Data

Measuring sections: 2300mm

– pipe section 1: steel, diameter: 1/2″, 90° pipe angle

– pipe section 2: steel, diameter: 1/2″, 90° pipe bend

– pipe section 3: copper, diameter: 18x1mm,90° pipe angle

– pipe section 4: copper, diameter: 18x1mm,90° pipe bend

Differential pressure meter

Measuring ranges- flow rate: 150…1600L/h- differential pressure: -350mbar…350mbar

Dimensions and Weight LxWxH: 1650x700x1850mmWeight: approx. 100kg

Required for Operation

Water connection: 1500L/h, drainlosses in a pipe system Vocational Training Equipment Educational Equipment

SR3005 losses in a pipe system Vocational Training Equipment Educational Equipment

Brand: ShouldShine

Model:SR3005

Learning Objectives / Experiments

– pressure curve in a closed pipe system with circulation pump

– influence of pipe diameter, flow velocity, change in

cross-section and pipe fittings on the pressure losses

– determination of pump characteristics, system characteristics and the operating point

Specification

[1] investigation of the pressure losses at contractions, pipe angles, pipe bends, valves and fittings and pipe elements of different diameter

[2] pipe elements are commercially standard components in heating and sanitary engineering

[3] clear panel mounted on a sturdy, movable frame

[4] closed water circuit with pump and tank

[5] integrated bleed valve on manometer and in the pipe section

[6] flow measurement using rotameter

[7] measurement of the pressure distribution at

13 pressure measuring points, display with 13 tube manometers

Technical Data

Pump – 3 stages – max. flow rate: 4,5m³/h – max. head: 6m

Tank: approx. 5L

Measuring range – flow rate: 100…1000L/h – pressure: 1600mmWC

Dimensions and Weight LxWxH: 1900x700x2020mm Weight: approx. 140kg

Required for Operation

230V, 50Hz, 1 phaseInstallation technology: losses in a pipe system Educational Equipment

SR3005 Installation technology: losses in a pipe system Technical Training Equipment Educational Equipment for college, university, technical schools.

Heat Transfer Bench Educational Equipment Thermal Training Equipment

SR1162E Heat Transfer Trainer Heat Transfer Bench Educational Equipment Thermal Training Equipment

1 Product Overview

1.1 Profile

This product is an extensible educational experiment equipment for students to observe the heating, cooling and air movement of the device during operation. Students can observe the mixing of air and conduct tests to monitor temperature and air pressure. Grasp its control principle and control method, cultivate students’ corresponding knowledge and skills, suitable for higher vocational schools, engineering university, secondary vocational school and technical school related professional teaching and skills training evaluation.

1.2 Feature

(1) The training platform adopts an aluminum column frame structure with a universal wheel at the bottom for flexible movement. The desktop uses a 25mm thick high-density substrate, and the surface is treated with high-temperature and high-pressure fire-resistant panels. The structure is firm and beautiful. The instrument and power supply are integrated and installed, which is easy to use and not easily damaged.

(2) The training platform has a good safety protection system.

2 Technical specifications

(1) Input Power: AC220V±10% 60Hz

(2) Fan: Supply voltage: AC220V/50Hz Power: 1.5kW; Maximum flow rate: 2.160m3/h

(3) Overall dimensions: 2000mm x 750mm x 2100mm

(4) Overall capacity: <2.5KVA

(5) Weight: <100kg

(6) Working conditions: Ambient temperature -10°C to +40°C Relative humidity <85% (25°C)

3 Product introduction

3.1 Power control panel

(1)The power control panel adopts an aluminum alloy frame and a closed box structure, which is integrated with the placement rack below.

(2)Configured with circuit breaker, power indicator, temperature adjustment knob, thermometer, power socket, differential pressure gauge, thermostat and intelligent electrical parameter measuring instrument

(3)The power input is controlled by the leakage breaker and the emergency stop control button is provided. In case of emergency, you press emergency stop button is so as to cut off the power.

3.2 Training workbench

(1)Training workbench:

The training table is supported by aluminum pillars, and the bottom universal wheel has a brake that can be moved and positioned flexibly. The desktop uses a 25mm thick high-density substrate, and the surface is treated with high-temperature and high-pressure fire-resistant panels. The structure is firm and beautiful.

(2) Heat exchange systemPlate Heat Exchanger Thermal Trainer Vocational Training Equipment

SR1158E Plate Heat Exchanger Thermal Trainer Vocational Training Equipment

I.Production profile

The key feature of plate heat exchangers is their compact design, in which optimum use is made of all of the material for heat transfer. The pressed in profile on the plates creates narrow flow channels, in which significant turbulence occurs. The turbulent flow allows effective heat transfer even with low flow rates and also has a self-cleaning effect. Plate heat exchangers are used in the food industry, offshore technology, refrigeration and domestic engineering.

II.Equipment feature

The SR1158E Plate Heat Exchanger is part of a series of units enabling experiments to be performed on different heat exchanger types. The experimental unit is ideally suited for investigating the functioning and behaviour of a plate heat exchanger in operation.

The plate heat exchanger is made up of profiled plates with water flowing through the spaces between them. The plates are soldered in such a way that two separate flow channels are formed. These are one “cold” and one “hot” flow channel, in an alternating arrangement. Part of the thermal energy of the hot water is transferred to the cold water. Valves on the supply unit are used to adjust the flow rates of hot and cold water. The supply hose can be reconnected using quick-release couplings, allowing the flow direction to be reversed. This allows parallel flow or counter flow operationspecification

[1] plate heat exchanger for connection

[2] hot and cold water supply

[3] parallel flow and counterflow operation possible

[4] six soldered plates

[5] recording of temperature

Technical Data

6 plates, stainless steel

Heat transfer area: 480cm²

Dimensions and Weight

LxWxH: 400x230x85mm

Weight: approx. 3kg

Brand: ShouldShine

Model: SR1158EZM6152 Heat Exchangers in the Refrigeration Circuit Technical Teaching Equipment

Jinan Should Shine Didactic Equipment Co., Ltd. is company specialized in manufacture and trading Fluid Lab Equipment,air conditioner trainer, refrigeration trainer, Thermal Lab Equipment, Vocational Training Equipment,Didactic Equipment,Engineering Educational Equipment,Technical Teaching Equipment,for university,college,technical institution, polytechnics.Should Shine products has been exported to America,Asia,Europe,Africa, Australia.