- Description

- Inquiry

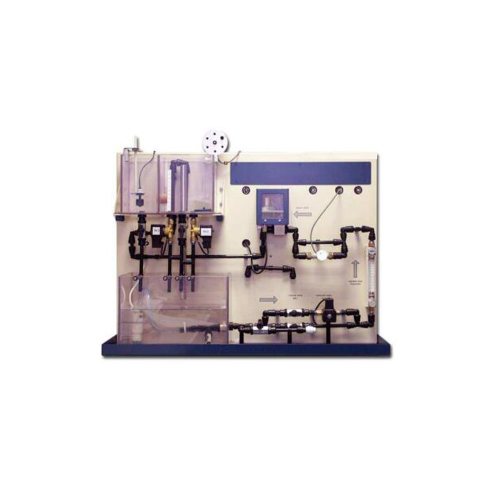

SS2106 flow and level Training equipment teaching Mechatronics Training Equipment

The device adopts an aluminum profile structure and integrates a variety of devices for liquid level control and flow control. It can be used to learn the process control principle and operation mode of two variables of flow and liquid level.

The electrical control part adopts a touch all-in-one machine with a touch screen as the main control element. The touch all-in-one machine is equivalent to a combination of a PLC and a touch screen (compatible with the Mitsubishi series PLC programming software), and various sensors are directly collected through the touch all-in-one machine The liquid level and flow rate are displayed on the touch screen in real time, and the corresponding parameters can be set through the touch screen to perform PID control on the flow and liquid level. The change curve of the corresponding parameters can also be displayed on the screen to understand the control changes more intuitively process.

configuration list:

- 1 table body

- 1 electrical control box with touch screen and configuration software

- 1 30L water storage tank

- 2 process water tanks

- 1 circulating water pump

- 1 rotameter

- 1 pulse flow sensor

- 1 liquid level transmitter

- 2 float switches

- 1 electric control valve

- 3 solenoid valves

- 1 PID controller

- 2 double-pipe pressure gauges

- 1 differential pressure gauge

- 1 set of valves and connecting pipelines

Overview

The level/process trainer is a single circulatory system that allows the study of principles

Process control uses liquid level and flow as measured process variables. The system is

A completely independent, low-pressure flowing water circuit, supported on a reference board, makes it suitable for individual student work or group presentations.

It consists of a dual-chamber process tank connected to a pool of manual and solenoid operated valves. Water is pumped through the system through a variable area flow meter and motor control valve. The liquid level is measured in the process tank. The flow rate is measured by an optical pulse flow meter.

Features

- Contains a choice of level and flow sensors and indicators

- Flow rate controlled by linear motor control valve

- On/Off and proportional control

- P, PI and full PID control and automatic adjustment function

Dual-loop control temperature trainer

Use water as process fluid

Course coverage

- Familiarization and calibration of process and level

- Interface familiarization and calibration

- Controller familiarization and calibration

- Float level transmitter

- Pulse flow transmitter

- Switch control

Research on level and flow of P, PI and PID control

- Optimize PID controller

- Advanced process control

-Configure valve to adjust flow

-Water tank: at least 30 liters

Pump:

-Maximum output flow: 30 L/min

-max HMT: 10 meters

Power supply: 24V DC

-Electrical panel

Will be powered by 220V/50Hz